6 Tips for Improving Chemiluminescence ELISA Precision

Chemiluminescence ELISA technology offers enhanced sensitivity with a very broad dynamic range. However, consistency in assay technique is especially important to ensure optimal performance from day-to-day and operator-to-operator. The following six tips may help to improve intra-assay and inter-assay precision when performing chemiluminescence immunoassays.

Tip 1: Use a Pipette to Transfer All Reagents to the Assay Plate

With any immunoassay, using a multichannel pipette to transfer reagents to the assay plate speeds loading time and improves well-to-well consistency. Standards and samples can be prepared in microtiter tubes (such as Simport Scientific Biotube™ Microtiter Tube System) or a dilution plate (such as Fisherbrand™ 96-Well DeepWell™ Polypropylene Microplates) then transferred to the assay plate using a multichannel pipette. This technique reduces the potential for pipetting errors. Carefully set up and follow plate maps for the dilution plate and assay plate when pipetting. For assay reagents that are added to all wells, a reagent reservoir and multichannel pipette are recommended.

Tip 2: Wash All Wells Thoroughly and Forcefully

Insufficient washing is a common cause of high background and reduced sensitivity in immunoassays. A hand-held pipettor should not be used to wash plates. An automated plate washer set to 300 µL per well or a hand-held washing manifold are recommended. When using a washing manifold, all wells should be over-filled for each wash step. Care should be taken not to touch the bottom surface of the wells with the manifold tips during aspiration or dispensing. Carefully observe the wash buffer as it is dispensed to ensure that no channels in the hand-held manifold are clogged. When using an automated washer, verify dispense volume prior to washing. If you are using a strip-well plate and manually decanting into a receptacle, squeeze the sides of the plate frame in the center to ensure the strips remain in place. It is sometimes helpful to number strips being used to track the proper location throughout the assay. Always complete the recommended number of washes for each wash step. Over-washing is not a problem, but under-washing can negatively affect assay sensitivity.

Tip 3: Blot with Lint-free Towels

After the last wash step, the plate should be inverted and tapped onto lint-free absorbent towels, such as Bounty paper towels, to capture residual wash buffer. Some towels can release small pieces of lint that adhere to plate wells and interfere with the assay, so avoid using those types. Blotting towels should be changed frequently. Remember to dry residual buffer from the plate frame following the final wash step. It is also important to proceed directly to the next assay step after blotting to prevent wells from drying out.

Tip 4: Ensure Consistent Shaking

The speed and type of shaking are very important for proper distribution of reagents throughout each well and consistency of assay kinetics. ALPCO recommends a plate shaker that employs an orbital motion with a very small radius set to a speed of 700 to 900 rpm. Traditional orbital shakers employing a large radius of motion can pull liquid toward the edges of the well, resulting in insufficient binding in the center of the wells. Shaking speed may need to be optimized for planar shakers involving a rapid side-to-side motion. Failing to shake at sufficient speed may negatively affect assay signal and sample recovery.

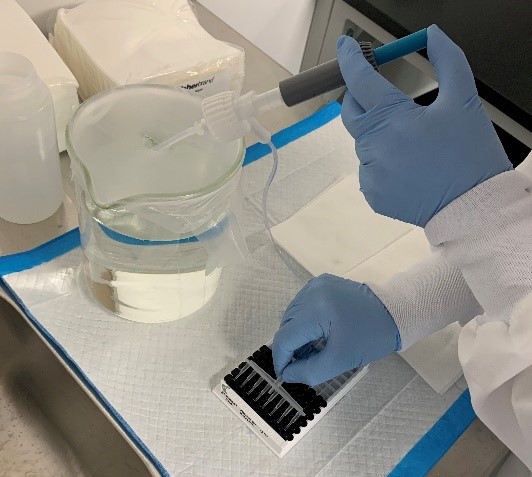

Tip 5: Prepare Fresh Substrate and Add with a Multi-Channel Pipette

Substrate solution should be prepared fresh prior to each use and kept in the dark prior to addition to the plate. For chemiluminescence immunoassays, it is particularly important to use a reagent reservoir and multichannel pipette to add substrate to the plate. Using these together ensures uniform timing and signal generation across the plate.

Tip 6: Carefully Follow Timing Instructions for Plate Reading

Once the substrate is added, the plates must be read within the time specified in the instructions for the specific assay being performed. For some chemiluminescence assays, the window for optimal signal production is just 2 to 5 minutes following addition of substrate. It is important to ensure that the plate reader is available, the assay template is pre-selected, and the instrument is ready to read prior to addition of the chemiluminescence substrate solution. Carefully monitoring the timing for this step will improve signal consistency between assays. For most ALPCO chemiluminescence ELISAs, the luminescence reader being used should be set to an integration (read) time of 1,000 ms (1 second) per well to ensure consistent detection from the beginning to the end of the plate. Refer to your assay’s instructions for specific instrument settings. Signal generation (actual Relative Fluorescence Units) will vary from one chemiluminescence reader to another, but extrapolated values should be consistent.

We’re Here to Help!

Chemiluminescence ELISAs offer labs many advantages compared to other types of immunoassays. Users can follow our 6 tips for improving chemiluminescence ELISA precision to help achieve optimal performance. For more tips and tricks for improving overall ELISA technique. Contact our technical solutions team at [email protected] or 800-592-5726 with any questions or for further assistance.